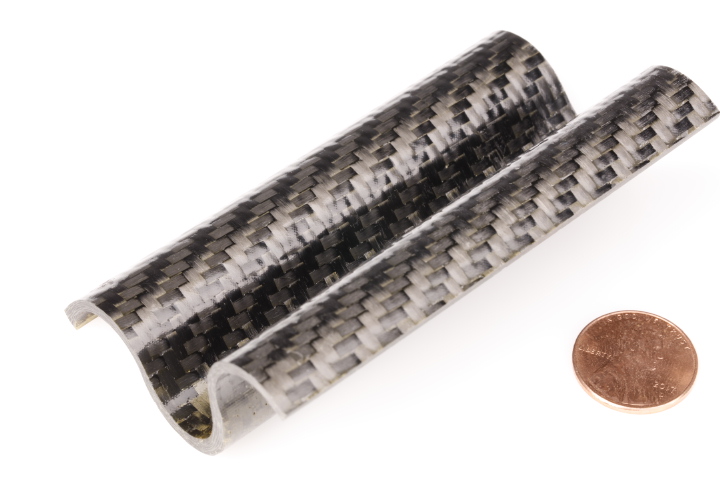

Frontal polymerization allows for rapid manufacturing of aerospace-grade carbon fiber composite parts with significantly less energy and comparable mechanical properties to current industry techniques.

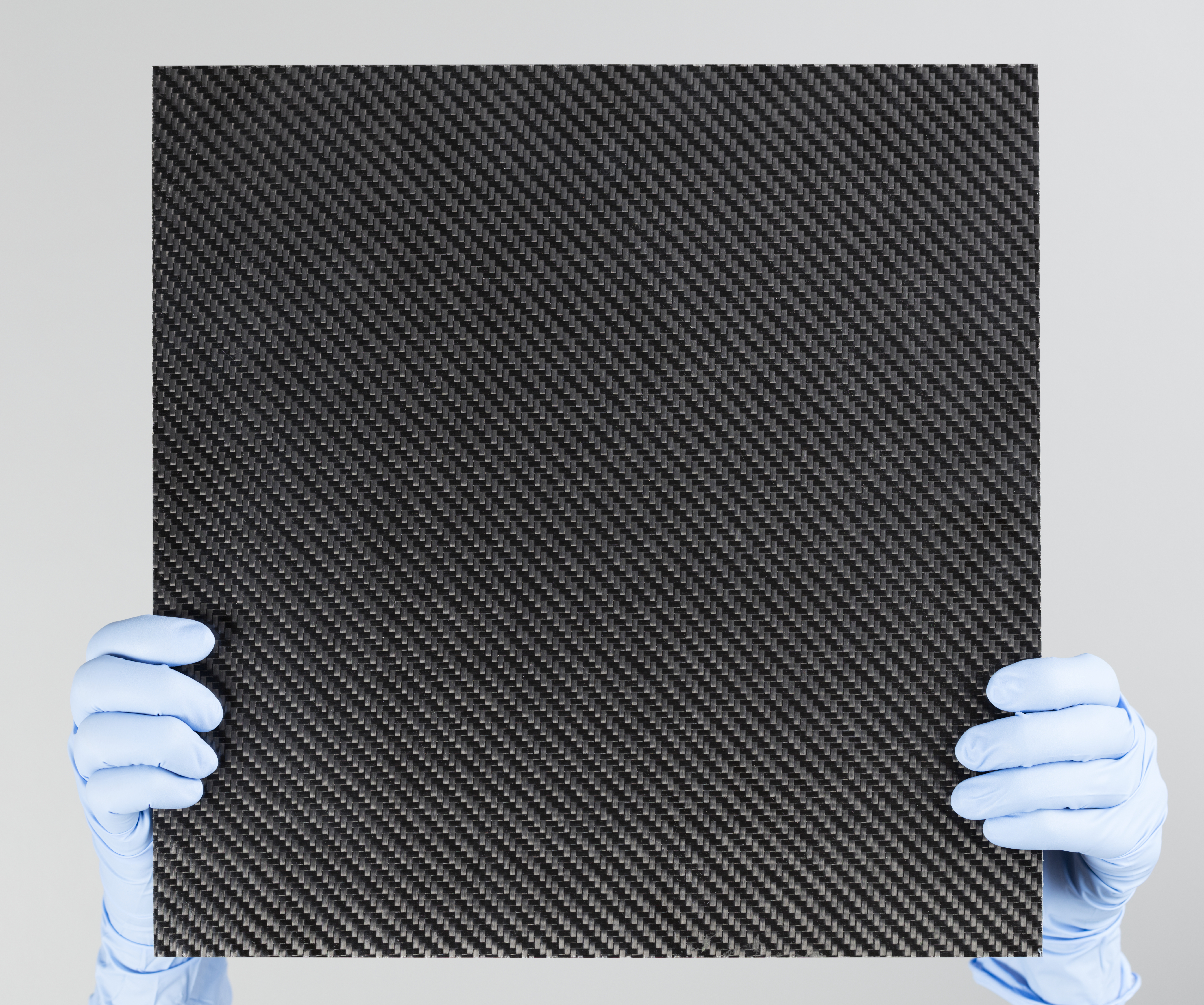

Manufacturing of a 4 inch by 8 inch composite panel can be achieved in under two minutes with frontal polymerization, while a conventional manufacturing would take hours to make a similar part. The infrared (IR) video below shows the temperature and curing of the carbon fiber composite when initiated from a single wire.

Manufacturing time can be cut in half by introducing another wire; reducing the time needed below one minute!